Ghana is making remarkable strides in diversifying its economy beyond traditional sectors such as agriculture and mining. The country’s foray into the aluminium industry has been a significant milestone in pursuing sustainable development and economic growth.

Ghana’s interest in the aluminium industry dates back to the 1960s when the Volta River Authority (VRA) established the Volta Aluminium Company (VALCO) in collaboration with Kaiser Aluminum and Reynolds Aluminium. VALCO, located in Tema, became Africa’s first aluminium smelter, leveraging the abundant supply of bauxite and the hydroelectric potential of the Volta River. Despite facing challenges and intermittent periods of operation, VALCO laid the foundation for Ghana’s aluminium industry.

Dr. Theophilus Acheampong and Dr. Matthew Tyce have highlighted the challenges and opportunities in Ghana’s aluminium industry, particularly in the context of the global clean energy transition.

The scholars’ work, published in ‘The Conversation’, discusses Ghana’s long-standing ambition to develop an integrated aluminium industry, which has been a focus since the country’s independence.

The vision, initiated by Kwame Nkrumah, aimed to utilize Ghana’s abundant bauxite reserves to produce aluminium domestically, with the Volta Aluminium Company (Valco) being a key player in this endeavour. Ghana’s bauxite reserves are estimated at 900 million tonnes, making it the second-largest reservoir in Africa after Guinea.

“Successive Ghanaian governments have pursued this strategy over the decades. The most recent push came in 2017 when the government embarked on its latest drive to develop an aluminium-producing capacity. Since then, the Ghana Integrated Aluminium Development Corporation (Giadec) has invested in new mines and is looking to partner with foreign and domestic companies to actualise a harmonised aluminium industry, including an alumina refinery.”

Dr. Theophilus Acheampong and Dr. Matthew Tyce

The authors noted that while heavy industries like aluminium production are crucial for economic transformation, moving from low productivity to high productivity activities, Ghana faces significant challenges.

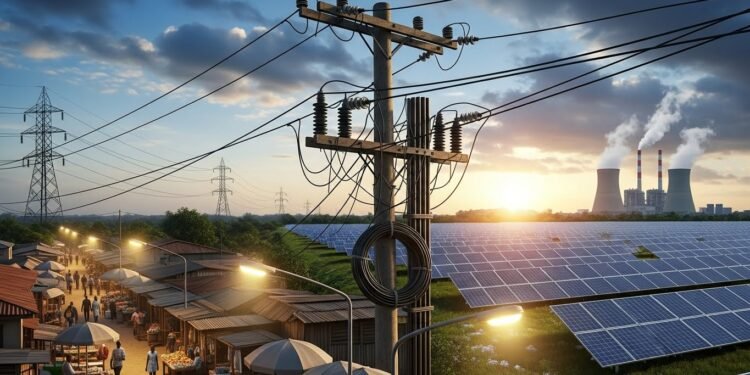

These include a lack of investment in new mines, insufficient electricity for smelting, and the inability to upgrade existing facilities like Valco. The push for an integrated aluminium industry is further complicated by the global shift towards cleaner energy sources and industrial decarbonisation.

The authors noted that Ghana’s efforts to develop its aluminium industry are also hindered by financial constraints, making it difficult to adopt the latest sustainable production technologies such as carbon capture, use, and storage (CCUS), and green hydrogen.

Additionally, Ghana faces “green taxonomies” from key export markets, including the European Union, which imposes requirements for monitoring and declaring emissions in products, potentially affecting Ghana’s export competitiveness.

“The third obstacle that Ghana faces revolves around how to make its refineries and smelters produce competitively priced aluminium. The cost of power is a sticking point as it has been in prior years. According to Ghana’s recently published National Energy Transition Framework, natural gas will serve as Ghana’s primary transition fuel. The government argues that it can provide the base load of electricity that Ghana requires for industrialisation.”

Dr. Theophilus Acheampong and Dr. Matthew Tyce

The choice of energy sources for Ghana’s aluminium industry is a critical issue. While natural gas is proposed as the primary transition fuel, it could jeopardize the export potential of Ghana’s aluminium, which is heavily reliant on Europe. Hydroelectricity, being the cheapest and greenest energy source, is seen as an ideal solution but faces political and environmental challenges, including the impact on electricity prices and the potential depletion of hydropower resources.

Another challenge lies in ensuring sustainable mining practices and environmental protection. The government must enforce strict regulations to prevent illegal mining activities and promote responsible mining practices to mitigate the negative environmental impact associated with bauxite extraction.

Partnerships, Key to Develop the Industry

To overcome these challenges, Ghana should continue to foster partnerships with international investors, leveraging their expertise and capital to develop a sustainable and competitive aluminium industry.

The authors suggested that Ghana needs clarity on how energy technologies will be classified at an international level, honouring climate financing and green technology transfer pledges from developed to developing economies.

The government must invest in research and development, technological innovation, and human capital development to enhance the industry’s productivity and competitiveness.

“We suggest the Ghanaian government can overcome some of these issues through dialogue with stakeholders and being frank about the trade-offs involved. But a national discussion about benefits and costs is only possible if it’s clearer what choices around energy will be made.”

Dr. Theophilus Acheampong and Dr. Matthew Tyce

Ghana’s development in the aluminium industry marks an important milestone in the country’s economic diversification efforts. The sector’s growth promises significant economic benefits, including job creation, infrastructure development, and increased export revenue.

By addressing infrastructure challenges, promoting responsible mining practices, and fostering partnerships with international investors, Ghana can unlock the full potential of its aluminium industry and pave the way for sustainable development.

READ ALSO: MIIF and Ghana Stock Exchange Advocate for Mining Sector Investment